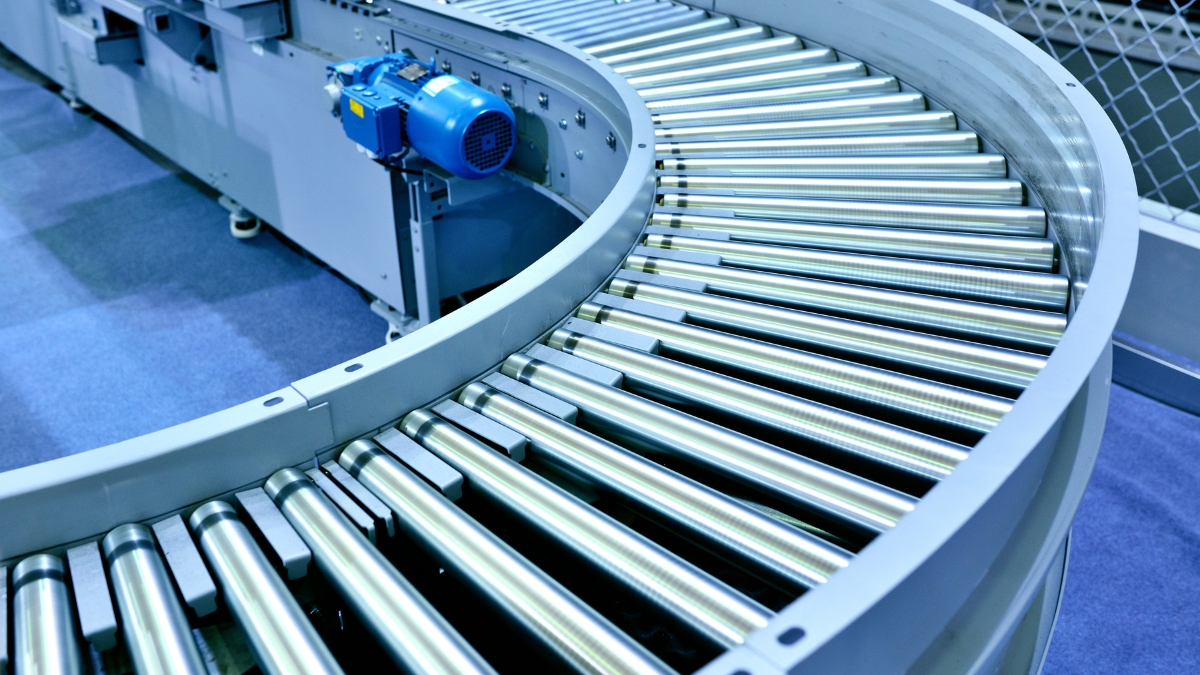

Conveyor systems are an integral part of various industries, from manufacturing and warehousing to packaging and distribution. They play a crucial role in efficiently transporting materials and products over varying distances, streamlining operations and increasing productivity. However, the effectiveness of a conveyor system hinges on its control system.

What is a Conveyor Control System?

A conveyor control system is a collection of hardware and software components that manage and regulate the operation of a conveyor system. It ensures that the system functions correctly, safely, and efficiently.

Key Components of a Conveyor Control System

Several key components work together to form a comprehensive conveyor control system:

Sensors: Sensors monitor various aspects of the conveyor system, such as the presence of materials, belt speed, and motor temperature. This data is crucial for the control system to make informed decisions.

Controllers: Controllers, often programmable logic controllers (PLCs), receive data from sensors and execute control algorithms to regulate the conveyor’s operation. They can control the speed, direction, and stopping and starting of the conveyor belt.

Human-Machine Interface (HMI): An HMI provides a user-friendly interface for operators to interact with the conveyor system. It allows operators to monitor system status, adjust settings, and troubleshoot issues.

Motors and Drives: Motors provide the power to drive the conveyor belt, while drives control the speed and direction of the motors.

Contact MBA Electric LLC today at (973)5562583 for more information!

Types of Conveyor Control Systems

Conveyor control systems can be broadly classified into two types:

- Standalone Control Systems: These systems are designed for simple conveyor systems with limited functionality. They typically consist of a PLC and a basic HMI.

- Integrated Control Systems: These systems are used for complex conveyor systems with multiple conveyors, sorting mechanisms, and other integrated equipment. They often incorporate advanced features such as supervisory control and data acquisition (SCADA) systems.

Benefits of Implementing a Conveyor Control System

Implementing a robust conveyor control system offers numerous benefits:

- Improved Efficiency: By optimizing conveyor operations, control systems can significantly enhance productivity and throughput.

- Enhanced Safety: Control systems can incorporate safety features such as emergency stops and speed limits to prevent accidents.

- Reduced Maintenance Costs: Predictive maintenance capabilities can help identify potential issues before they escalate, reducing downtime and maintenance costs.

- Better Quality Control: By monitoring and controlling various parameters, control systems can help ensure product quality and consistency.

Did You Know?

Conveyor control systems can be integrated with other factory automation systems, such as warehouse management systems (WMS) and enterprise resource planning (ERP) systems, to create a seamless and efficient supply chain.

If you are looking to upgrade or implement a conveyor control system, MBA Electric LLC can help. Our team of experts has extensive experience in designing and installing conveyor systems for various industries. We offer tailored solutions, ensuring seamless integration and optimal performance. Let us streamline your operations with our expertise. Contact us today at (973)5562583 to learn more.