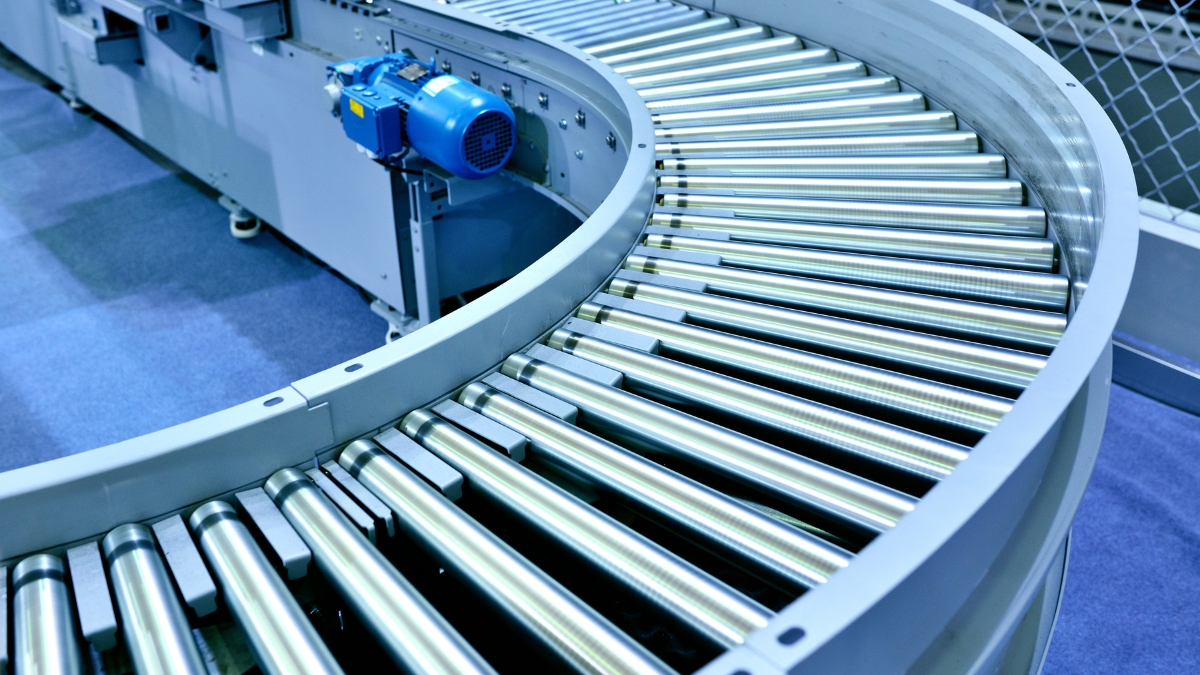

In today’s fast-paced digital world, reliable and efficient communication systems are essential for businesses of all sizes. For industrial settings, where operations often depend on real-time data exchange and control, a robust and resilient network infrastructure is paramount. Industrial network cabling plays a crucial role in enabling seamless communication between various devices, machines, and systems, ensuring smooth and uninterrupted operations.

Understanding Industrial Network Cabling

Industrial network cabling involves the installation and maintenance of specialized cabling systems designed to withstand the harsh and demanding environments typically found in industrial facilities. These cables are engineered to handle high temperatures, vibrations, electromagnetic interference (EMI), and other environmental factors that can compromise the integrity of standard network cables.

Key Components of Industrial Network Cabling

Several critical components contribute to a robust industrial network cabling system:

- Industrial-grade cables: These cables are constructed with high-quality materials and robust shielding to protect against EMI, mechanical stress, and extreme temperatures. Common types include shielded twisted pair (STP), fiber optic cables, and coaxial cables.

- Connectors and terminations: Reliable connectors and terminations are essential for ensuring secure and error-free data transmission. Industrial-grade connectors are designed to withstand harsh environments and provide a secure connection.

- Cable management: Proper cable management is crucial for maintaining a clean, organized, and efficient network infrastructure. Cable trays, conduits, and other management systems help protect cables from damage and facilitate easy maintenance.

- Network devices: Network devices such as switches, routers, and servers form the backbone of an industrial network. These devices must be selected based on the specific requirements of the application and the environment.

Contact MBA Electric LLC at (973) 556-2583 for more information!

Benefits of a Well-Designed Industrial Network Cabling System

Investing in a well-designed and properly installed industrial network cabling system offers numerous benefits:

- Enhanced productivity: A reliable network infrastructure enables seamless communication between devices, machines, and systems, leading to increased efficiency and productivity.

- Improved safety: Industrial networks can be used to monitor critical equipment, detect potential hazards, and implement safety protocols, reducing the risk of accidents.

- Reduced downtime: A robust network infrastructure minimizes downtime due to network failures, ensuring continuous operations and maximizing production.

- Cost savings: By optimizing network performance and reducing maintenance costs, a well-designed network cabling system can help businesses save money in the long run.

- Future-proof scalability: A flexible and scalable network infrastructure can accommodate future growth and technological advancements, ensuring that the network can adapt to changing business needs.

Did you know?

A poorly designed or installed network cabling system can lead to significant performance issues, including slow data transfer speeds, frequent network outages, and security vulnerabilities.

Best Practices for Industrial Network Cabling

To ensure a robust and resilient industrial network cabling system, it is essential to follow best practices:

- Thorough planning and design: A detailed network design is crucial for determining the appropriate cabling infrastructure, considering factors such as the network topology, bandwidth requirements, and environmental conditions.

- Use of high-quality materials: Only use industrial-grade cables, connectors, and other components that meet or exceed industry standards.

- Proper installation techniques: Adhere to industry standards and best practices for cable installation, including proper termination, grounding, and shielding.

- Regular maintenance and testing: Conduct regular network maintenance and testing to identify and address potential problems before they cause major disruptions.

- Professional installation: Engage experienced and qualified professionals for network cabling installation and maintenance to ensure optimal performance and longevity.p

If you’re looking to upgrade your industrial network cabling or need assistance with network design and installation, contact MBA Electric LLC at (973) 556-2583. Our team of experts can help you build a robust and resilient network infrastructure that meets your specific needs and supports your business goals.