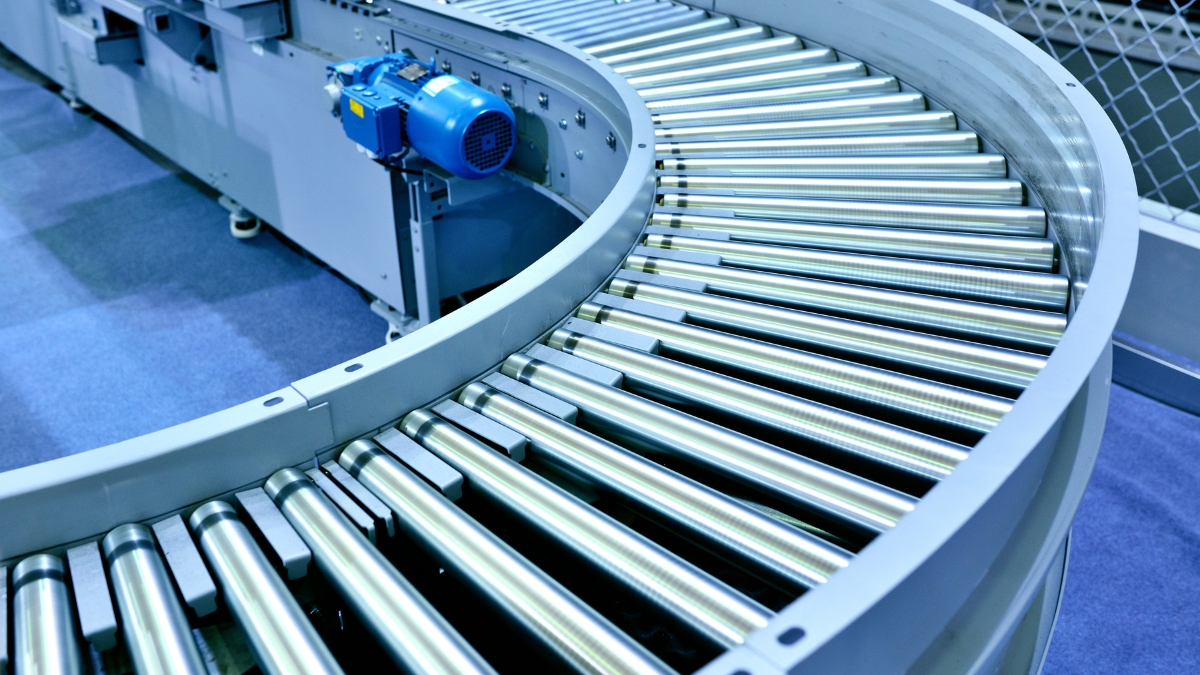

Conveyor systems are essential for many industries, including manufacturing, warehousing, and distribution. They are used to move materials and products from one location to another, often at high speeds. In order to ensure that these systems operate efficiently and safely, it is important to have a good understanding of conveyor control.

What is Conveyor Control?

Conveyor control is the process of managing the movement of materials and products along a conveyor system. This can include controlling the speed of the conveyor, stopping and starting the conveyor, and directing materials to different locations.

Contact MBA Electric LLC at (973) 556-2583 for more information

Why is Conveyor Control Important?

Conveyor control is important for a number of reasons, including:

- Safety: Conveyor systems can be dangerous if they are not properly controlled. By controlling the speed and movement of the conveyor, you can help to prevent accidents.

- Efficiency: Conveyor control can help to improve the efficiency of your operations. By controlling the flow of materials, you can reduce bottlenecks and improve throughput.

- Accuracy: Conveyor control can help to improve the accuracy of your operations. By controlling the movement of materials, you can ensure that they are delivered to the correct location.

How is Conveyor Control Achieved?

Conveyor control can be achieved through a variety of methods, including:

- Mechanical controls: Mechanical controls are used to control the movement of the conveyor belt. This can include using switches, levers, and pulleys.

- Electrical controls: Electrical controls are used to control the speed and direction of the conveyor belt. This can include using motors, sensors, and programmable logic controllers (PLCs).

- Software controls: Software controls are used to manage and monitor the conveyor system. This can include using supervisory control and data acquisition (SCADA) systems.

Conveyor Control for High-Speed Sorting and Packaging

In high-speed sorting and packaging operations, conveyor control is essential for ensuring that products are moved quickly and accurately. A variety of conveyor control technologies are used in these operations, including:

- High-speed sorting systems: These systems use a variety of sensors and controls to sort products at high speeds. This can include using barcode scanners, weight sensors, and vision systems.

- Automated guided vehicles (AGVs): AGVs are used to move products around a warehouse or factory. They are equipped with sensors and controls that allow them to navigate around obstacles and follow a predetermined path.

- Robotics: Robots are used to perform a variety of tasks in high-speed sorting and packaging operations. This can include picking and placing products, packing products into boxes, and palletizing products.

Did you know?

Did you know that conveyor systems are used in a variety of industries, including manufacturing, warehousing, and distribution? They are also used in a variety of applications, such as food processing, automotive manufacturing, and e-commerce fulfillment.

If you are looking for a company that can help you with your conveyor control needs, please contact MBA Electric LLC at (973) 556-2583. We have over 25 years of experience in the design, installation, and maintenance of conveyor systems. We can help you to design and implement a conveyor control system that meets your specific needs.